Small-scale.

Compact design, but operates at 40,000 capsules/hour.

Pharmaceutical equipment for capsules

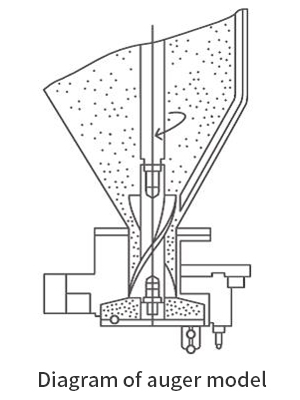

Fully-automatic filling machine that uses an auger to pressure-fill powdered materials that cannot be filled by die compression or mechanical vibration.

Suited to health foods.

The screw-type auger filling mechanism is suitable for powders that cannot be filled by die compression or mechanical vibration.

Compact design, but operates at 40,000 capsules/hour.

Both the cap segment and body disc have excellent separation accuracy, making re-assembly even easier after conversion, disassembly, and cleaning.

With slow capsule movement, the filling product is pressure-fed directly into the body by the auger. Various powder types, regardless of flowability or angle of repose, can be filled with high accuracy. The auger used for powder filling is removed, and granules are stirred as they are transferred to capsule bodies.