Advantages of Hard Capsules

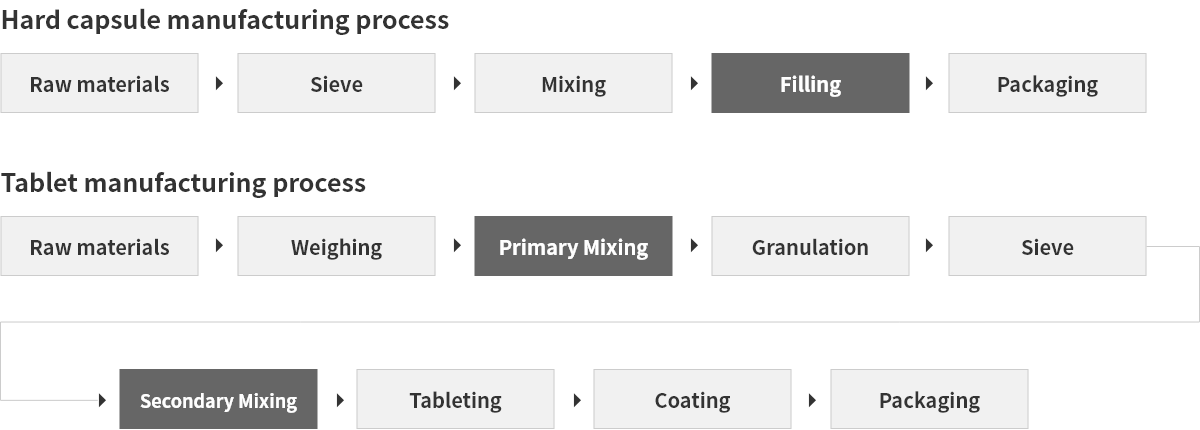

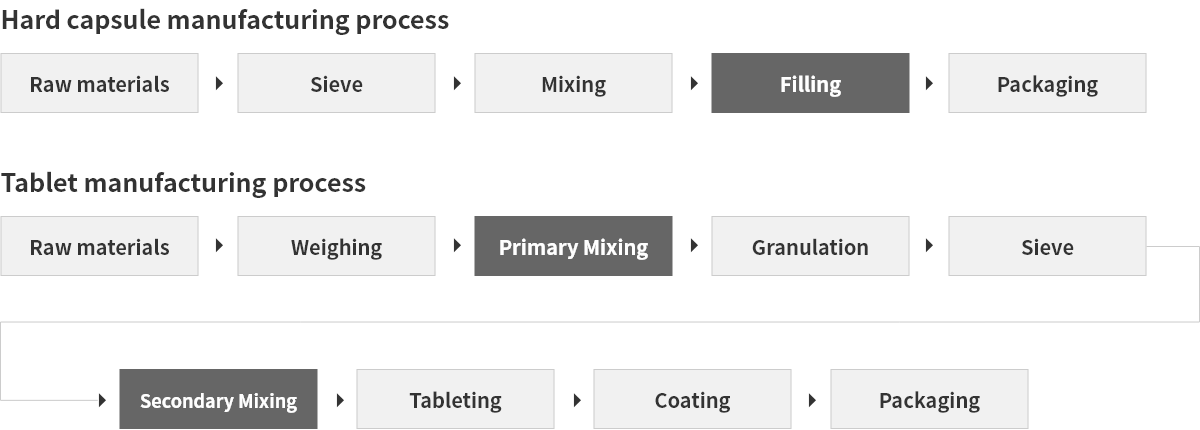

1. Shortened development time

Compared with tablets, hard capsules generally require fewer manufacturing steps, allowing for faster product development.

2. Protection of filling

Physical factors in the manufacturing process that can cause quality deterioration, such as heating and pressure, can be reduced. In addition, the amount of additives used can be reduced.

3. Masking effect

Masking the bitter taste and odor of the filling contributes to improved treatment compliance.

4. Various types of filling

Hard capsules can be filled with two or more types of solid preparations such as granules, tablets and mini tablets.

Oily liquid preparations and semi-solid preparations can also be incorporated into capsules by band sealing.

Powder

Powder Tablets

Tablets Liquid

Liquid Granules

Granules Hybrid dosage forms

Hybrid dosage forms

5. Enhanced distinguishability

Hard capsules can be colored or printed to make them stand out.

A wide variety of colors can be created by using tar dyes, natural dyes, and titanium oxide.

Text, marks, or other graphics can be printed in the specified ink color.

In addition to offset printing using ink, laser printing is also available.